Table of Contents

Torque Standards for Power Packages

The recommendations below are based on current data. As more sources are found, these recommendations may change.

Recommendations

STMicroelectionics

Comprehensive data and test results for various packages is provided in STMicroelectronics' TN12251). Their data is reproduced verbatim below:

| Package | Typical torque (N*m) | Maximum torque (N*m) |

|---|---|---|

| TO-220 | 0.55 | 0.70 |

| TO-220FP | 0.55 | 0.70 |

| TO-247 | 0.55 | 1.00 |

| TO-247-4 | 0.55 | 1.00 |

| TO-3P | 0.55 | 1.00 |

| TO-3PF | 0.55 | 1.00 |

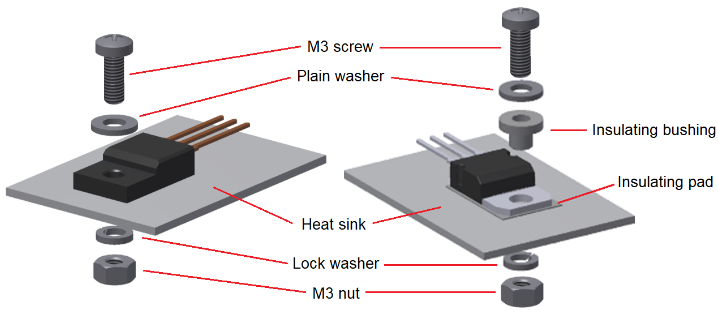

The kind of insulator (mica, silicone, etc.) isn't specified. M3 hardware was used in this note, and I don't expect using #4-40 screws (about 5% thinner than M3) with proper washers to change things significantly. Details of the hardware stackup are shown below.

STMicroelectronics' AN260 reference provides empiric data for a number of packages not covered above, over a range of torques and using mica insulators.2) These data show marginal to no improvement in thermal resistance above 50Nxcm, which corroborates the 0.55 N*m typical figure given in the previous table.

However, the maximum torque is slightly contradicted here (emphasis added):

Suggested maximum torques for M3 screws are 80Nxcm for TO220, PENTAWATT, HEPTAWATT, MULTIWATT and CLIPWATT 19 H packages. Particularly for FLEXIWATT package, clipping system is strongly recommended. While suggested maximum torque for M3 screws is 70 Nxcm for TO220SG (single gauge).

This leads to the following table for packages covered by this note.

| Package | Typical torque (N*m) | Maximum torque (N*m) |

|---|---|---|

| TO-220SG | 0.55 | 0.70 |

| TO-220 | 0.55 | 0.80 |

| Pentawatt | 0.55 | 0.80 |

| Heptawatt | 0.55 | 0.80 |

| Multiwatt | 0.55 | 0.80 |

| Clipwatt | 0.55 | 0.80 |

| FLEXIWATT | use clip | use clip |

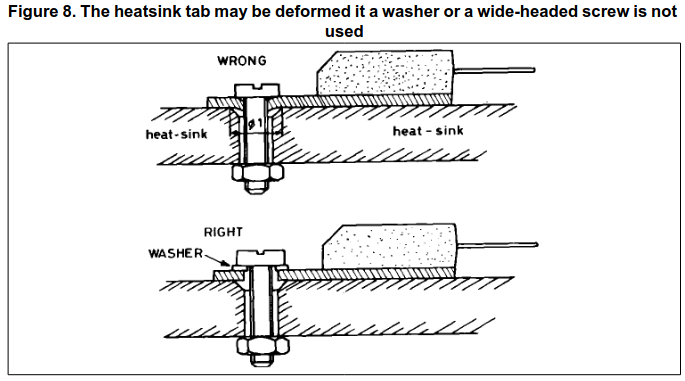

The hardware stackup shows only a screw entering the device tab through an optional washer and a bolt on the heatsink side:

Data from other sources

Infineon

Infineon ran a test on TO-247 packages with torques ranging from 0.2 N*m to 2 N*m.3) No failures were reported. However details of the test (e.g., what they consider “standard thermal cycles”) are lacking. Infineon also recommends using the torque specified in datasheets. It's hasn't been confirmed that Infineon provides this specification for their parts, but it is known that these data are absent from a substantial number of other manufacturer's datasheets.

Texas Instruments

TI mentions 50N-cm as the recommended maximum for their multi-lead TO-247 packages.4) How well this translates to other packages is unknown, but it does put the figure in the same ballpark as STMicroelectronics' recommendations.

onsemi

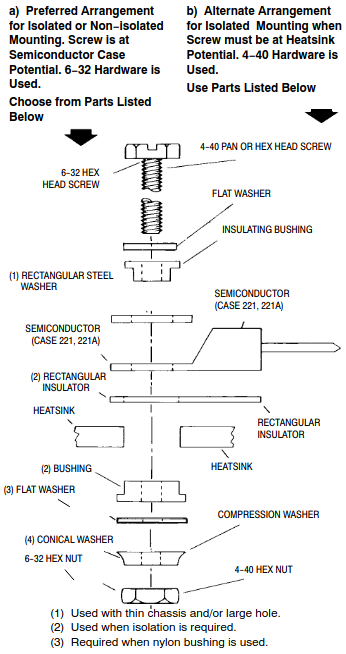

onsemi's AN1040/D5) advocates the use of conical “Belleville” washers for mounting devices:

However, the text implies that torque cannot be used to set the device pressure with conical washers because, “The assembler applies torque until the washer depresses to half its original height. (Tests should be run prior to setting up the assembly line to determine the proper torque for the fastener used to achieve 50% deflection.” Thus, it appears the washer determines the pressure on the device rather than torque on the screw, because torque on the screw is determined by the amount needed to compress the washer just right.

Perhaps not surprisingly then, specific torque ratings are difficult to derive from this note. However, it shows for TO-220 packages remarkable consistent thermal resistances for greased mica mounting with unspecified hardware over 2 to 6 in-lbs (0.23 to 0.68 N*m). One table shows a torque of 8 in-lbs (0.90 N*m) used with a TO−220AB device.